10 Common Transformer Types You Need to Know

Hey friends! We are going to talk about a very interesting topic today: transformers! No, not the shape-shifting robots, but the vital components in power transmission. You may find this topic a bit dry, but trust me, after learning about these common transformer types, you will think how cool these devices work and function!

Introduction

Transformers are an essential component of the modern electrical power system, and their importance cannot be overstated. They are used to transfer electrical energy from one circuit to another, and play a crucial role in the generation, transmission, and distribution of electricity. Whether stepping up or stepping down voltage levels, transformers are a key element in the efficient and reliable delivery of electrical power to homes, businesses, and industries worldwide.

Understanding the different types of transformers and their applications is vital for anyone working in the field of electrical engineering. This article aims to provide an overview of ten common types of transformers, including their definitions, operating principles, and typical applications. By the end of this article, readers should have a better understanding of the role that transformers play in the world of electrical power, and the various types available to meet different needs.

What are the types of common transformers?

There are many types of transformers, today we only discuss several common types of transformers, as follows:

See if there are any types of transformers you want to know, and we will explain them one by one below.

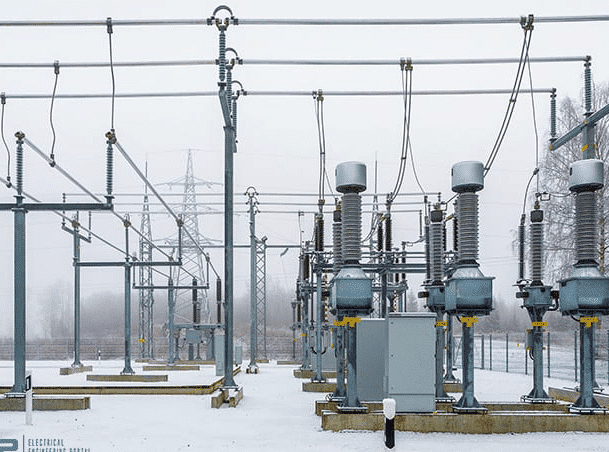

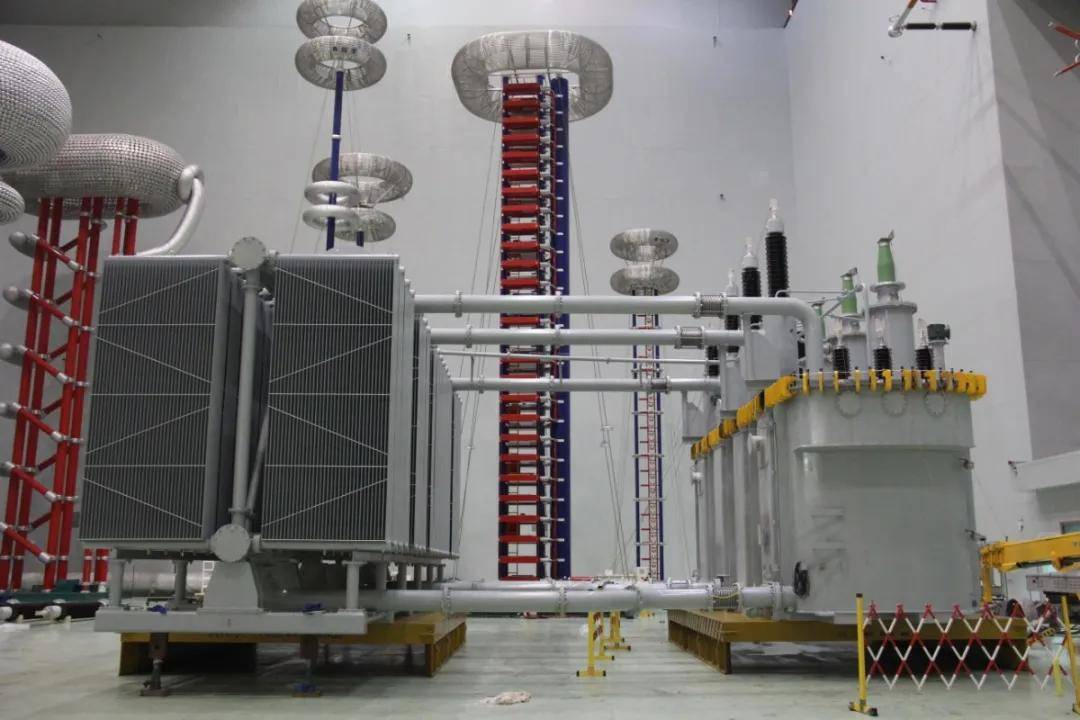

Power transformer

Power transformers are electrical devices that are designed to transfer electrical energy from one circuit to another circuit, typically at different voltage levels, without changing the frequency of the electrical signal. The primary function of a power transformer is to step up or step down the voltage of an AC power supply in order to match the voltage requirements of a particular application.

Power transformers consist of two or more coils of wire, known as windings, that are wound around a common magnetic core. The windings are electrically isolated from each other, but are magnetically linked together by the core. When an alternating current flows through the primary winding, it creates a magnetic field that induces a voltage in the secondary winding.

The voltage ratio of the primary to secondary winding is determined by the number of turns in each winding. For example, a transformer with a primary winding of 100 turns and a secondary winding of 50 turns would step down the voltage by a factor of two.

Power transformers are used in a wide range of applications, including power generation, transmission and distribution, as well as in various types of electrical equipment such as motors, generators, and electronic devices. They play a crucial role in providing a reliable and efficient supply of electrical power to homes, businesses, and industries around the world.

Types of power transformers (step-up, step-down, autotransformers)

There are several types of power transformers, including:

Step-up transformers – These transformers increase the voltage of an electrical signal from the primary winding to the secondary winding. Step-up transformers are commonly used in power generation and transmission systems to raise the voltage of electrical energy for efficient long-distance transmission.

Step-down transformers – These transformers decrease the voltage of an electrical signal from the primary winding to the secondary winding. Step-down transformers are commonly used in power distribution systems to lower the voltage of electrical energy for safe use in homes and businesses.

Autotransformers – These transformers have a single winding that is shared by both the primary and secondary circuits. They are used to either step up or step down voltage levels depending on the location where they are used. Autotransformers are commonly used in applications where a small voltage change is required, such as in electronic equipment and lighting systems.

Each type of power transformer has its own specific characteristics and applications, and is designed to meet the voltage requirements of a particular system or device.

Applications of power transformers

Power transformers have a wide range of applications in various industries, some of which include:

- Electrical Power Generation: Power transformers are used to step up the voltage of electrical power generated at power plants and transmit it over long distances through high-voltage transmission lines.

- Electrical Distribution: Distribution transformers are used to step down the voltage of electrical power to a safe and usable level for commercial and residential use.

- Industrial Applications: Power transformers are used in various industrial applications, such as in steel mills, chemical plants, and oil refineries, where high voltage is required to power heavy equipment.

- Renewable Energy: Power transformers are used in renewable energy systems, such as wind turbines and solar power plants, to transform the power generated into a form that can be transmitted to the grid.

- Railways: Power transformers are used in railways to step down the high voltage power from overhead lines to a level that can be used to power trains.

- Mining: Power transformers are used in mining operations to supply power to heavy-duty machinery used in mining activities.

- Marine Applications: Power transformers are used in marine applications, such as ships and offshore platforms, to supply power to the onboard equipment and systems.

- Military Applications: Power transformers are used in military applications, such as radar systems and communication equipment, to supply power to critical systems.

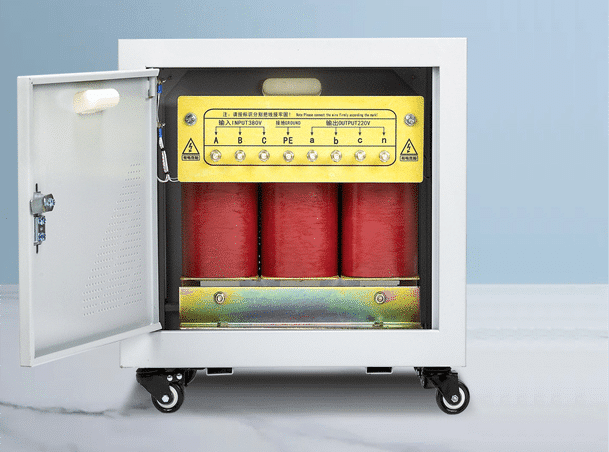

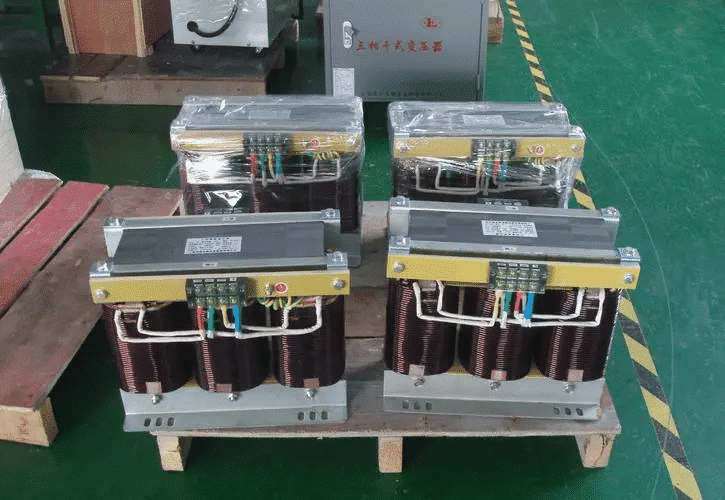

Distribution Transformers

A distribution transformer is an electrical transformer that is used to step down the voltage of electrical power to a level that is safe and usable for commercial and residential use. Distribution transformers are typically used in the final stages of power distribution, where the power is delivered to homes, businesses, and other low-voltage applications.

The function of a distribution transformer is to reduce the voltage of the electrical power that is transmitted through high-voltage transmission lines to a level that is safe and usable for appliances and equipment. The voltage level is reduced by using a series of coils of wire wrapped around a magnetic core.

The primary coil of the transformer is connected to the high-voltage power transmission line, while the secondary coil is connected to the low-voltage distribution line that supplies power to homes and businesses. The transformer works on the principle of electromagnetic induction, where the changing magnetic field created by the primary coil induces a voltage in the secondary coil.

Distribution transformers come in a range of sizes and voltage ratings, depending on the specific application. They are typically designed to operate at lower voltages than power transformers, which are used in the initial stages of power transmission.

In addition to stepping down the voltage of electrical power, distribution transformers also provide isolation and protection from electrical faults. They are designed to withstand overloads and short circuits, and are equipped with various protective devices, such as fuses and circuit breakers, to ensure safe and reliable operation.

Types of Distribution Transformers

There are several types of distribution transformers used in electrical power systems. Here are some of the most common types:

- Single phase distribution transformers: Used in single-phase power distribution systems, typically to step down high voltages to low voltages for use in homes and businesses.

- Three phase distribution transformers: Used in three-phase power distribution systems, typically to step down high voltage to low voltage for industrial and commercial applications.

- Pedestal mounted distribution transformers: designed for installation on concrete plinths for use in underground power distribution systems.

- Pole mounted distribution transformers: mounted on utility poles for overhead power distribution systems.

- Oil-filled distribution transformers: These transformers are filled with insulating oil, which helps cool the transformer and insulate the windings.

- Dry-type distribution transformers: This transformers do not use oil for cooling and are instead cooled by air or other gases. They are typically used in indoor applications where oil-filled transformers are not practical.

Application field of distribution transformer

Distribution transformers can be used in a wide range of applications, including:

| Application Field | Description |

|---|---|

| Power distribution | Distribution transformers are essential in distribution networks to step down high voltages on transmission lines to lower voltages suitable for homes, businesses and other facilities. |

| Industrial applications | Various industrial applications such as mining, steel mills, chemical plants, and other heavy industries provide low voltage power to a variety of equipment and machinery. |

| Renewable energy | Used in renewable energy systems such as wind farms and solar power plants to boost low-voltage electricity generated by renewable energy sources to a higher voltage suitable for transmission to the grid. |

| Rural electrification | Rural areas use to power homes and businesses. These transformers are usually smaller in size and have a lower voltage rating than those used in urban areas. |

| Transportation | For transportation systems such as trains, subways and electric vehicles, it provides electricity to the motors that drive the vehicles. |

| Emergency power supply | Hospital and other emergency power supply systems |

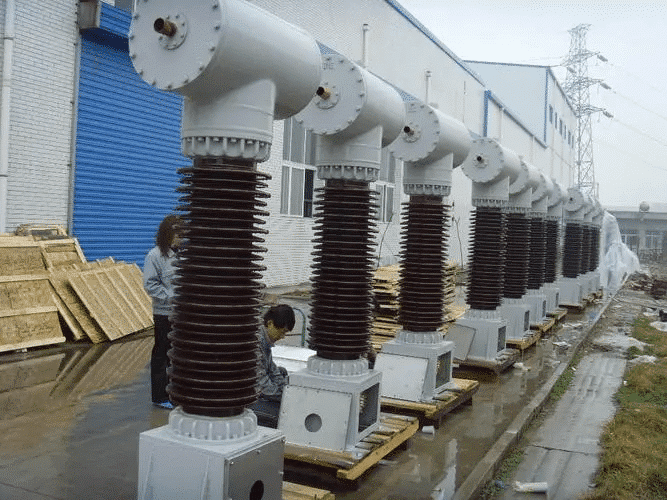

Instrument transformers

Instrument transformers are devices used in electrical power systems to measure high levels of voltage and current safely and accurately. They work by stepping down the high voltage and current levels to lower, measurable levels, which can be safely used by meters and other instruments.

Current transformers are used to measure current, while voltage transformers are used to measure voltage. They help to ensure the safety of personnel working with electrical equipment, provide accurate measurements for monitoring and control, and improve the reliability of power systems. By using instrument transformers, electrical equipment can be made smaller and less expensive, which can save money in the long run.

Types of Instrument transformers

There are two main types of instrument transformers used in electrical power systems:

- Current Transformers (CTs): Current transformers are used to measure the high currents in power systems by stepping down the current to a lower and safe level that can be accurately measured by instruments. CTs are commonly used in power systems for metering, protective relaying, and fault detection.

- Voltage Transformers (VTs) or Potential Transformers (PTs): Voltage transformers are used to measure the high voltages in power systems by stepping down the voltage to a lower and safe level that can be accurately measured by instruments. VTs are commonly used in power systems for metering, protective relaying, and fault detection.

Instrument transformers Fields of application

| Application | Description |

|---|---|

| Metering | Accurately measure electricity such as voltage and current for billing and accounting purposes. This helps in determining the amount of electricity consumed by customers and ensures fair billing. |

| Relay Protection | Transformers are used to provide accurate electrical measurements to protective relays which are responsible for detecting and isolating faults in the power system. These relays can then take appropriate action to protect the power system from damage and prevent power outages. |

| Fault Detection | Transformers help in detecting and locating faults in the power system. They provide accurate electrical measurements that can be used to identify the location and type of fault. This information is essential for maintenance and repair of the power system, thereby ensuring its reliability. |

| Load Management | Transformers are used to monitor the electrical load of the power system and make adjustments as needed to maintain system stability and reliability. This helps in preventing power outages and ensuring that the power system operates efficiently. |

| Renewable Energy | Transformers are used to measure the amount of electricity generated by renewable energy sources such as |

Autotransformers

An autotransformer is a type of transformer that has a single winding that serves as both the primary and secondary winding. Autotransformers are used in electrical power systems to transfer electrical energy between circuits at different voltage levels. They work on the principle of electromagnetic induction, where a varying magnetic field induces an electrical current in a nearby conductor.

They offer several advantages over conventional transformers, including smaller size, lower cost, higher efficiency, and variable voltage output. Due to their versatility, autotransformers are used in a wide range of applications in electrical power systems and other fields.

Type of Autotransformer

There are two main types of autotransformers:

- Two-winding autotransformer: Has two separate windings, with one winding serving as the primary and the other serving as the secondary. The two windings are connected electrically, and the transformer functions like a conventional transformer.

- Multi-tapped autotransformer: Usually this type of autotransformer has a single winding with multiple taps that allow for different voltage ratios. By tapping the winding at different points, the transformer can provide variable voltage output. Multi-tapped autotransformers are commonly used for voltage regulation and motor starting applications.

Both types of autotransformers have their own advantages and disadvantages depending on the specific application. Two-winding autotransformers are typically used in applications where the voltage ratio needs to be fixed, while multi-tapped autotransformers are used in applications where variable voltage output is required.

Autotransformer application field

Autotransformers are used in a variety of applications, including:

Voltage regulation: It can be used in the power system to regulate the voltage by adjusting the voltage ratio.

- Motor Start: Starts large electric motors, providing a reduced voltage during start-up.

- Audio equipment: Match the impedance of different audio components.

- Power transmission: step up or step down as needed.

- Power distribution: to reduce voltage levels for home, business and industrial use.

- Rail electrification: step up or step down voltage levels as required.

- Welding: Provide the high current required for welding.

Isolation transformers

An isolation transformer is a type of transformer that is used to provide electrical isolation between two circuits. It has a primary winding that is connected to the power source and a secondary winding that provides the isolated output voltage. The primary and secondary windings are electrically separated from each other, which provides a high degree of isolation between the input and output circuits.

Isolation transformers are used to ensure electrical safety in situations where people or equipment may be at risk of electric shock.

They work by providing a barrier between the input and output circuits, which helps to reduce the risk of electric shock.

Additionally, isolation transformers can help to reduce electrical noise and interference between circuits, which can improve the performance of sensitive equipment.

They can also create a separate grounding system for sensitive equipment, which can help to reduce the risk of electrical interference and damage.

Isolation transformers can also regulate voltage levels and provide stable power output to sensitive electronic equipment, making them a useful tool in a wide range of applications.

Type of isolation transformer

- There are 5 common types of isolation transformers, as follows:

- Single Phase Isolation Transformer: A primary winding and a secondary winding used to provide electrical isolation and voltage regulation in single phase power systems.

- Three-phase isolation transformer: Three primary windings and three secondary windings, used to provide electrical isolation and voltage regulation in three-phase power systems.

- Self-Wound Isolation Transformer: One winding, partially tapped to provide primary and secondary functions. It is used in applications where the input and output voltages are similar.

- Faraday Shielded Isolation Transformer: A shield is placed between the primary and secondary windings to help reduce electrical noise and interference between circuits.

- K-Factor Isolation Transformers: Designed to handle non-linear loads, such as those found in computer and telecommunications equipment. It provides electrical isolation and helps reduce harmonic distortion.

Isolation Transformer Application

Isolation transformers are used in a wide range of applications, including:

- Medical Equipment: Provides electrical isolation for medical equipment to protect patients from electric shock.

- Audio equipment: to reduce electrical noise and interference between circuits.

- Power Conditioning: Provides stable, clean power output for sensitive electronic equipment.

- Telecommunications: Isolate input power to protect equipment from electrical interference and damage.

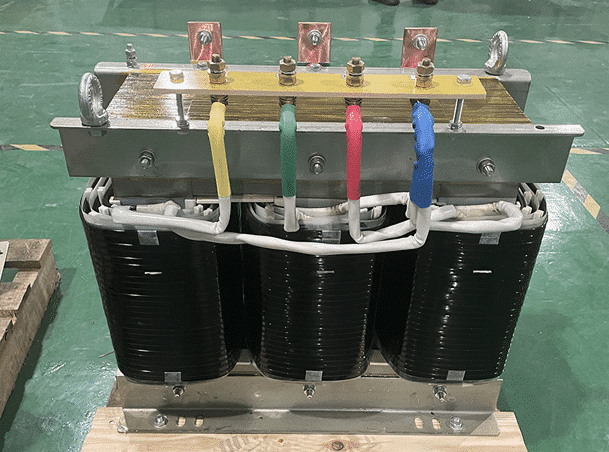

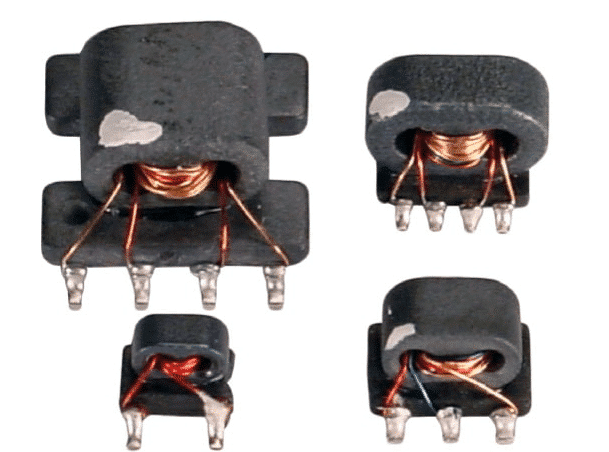

Control transformers

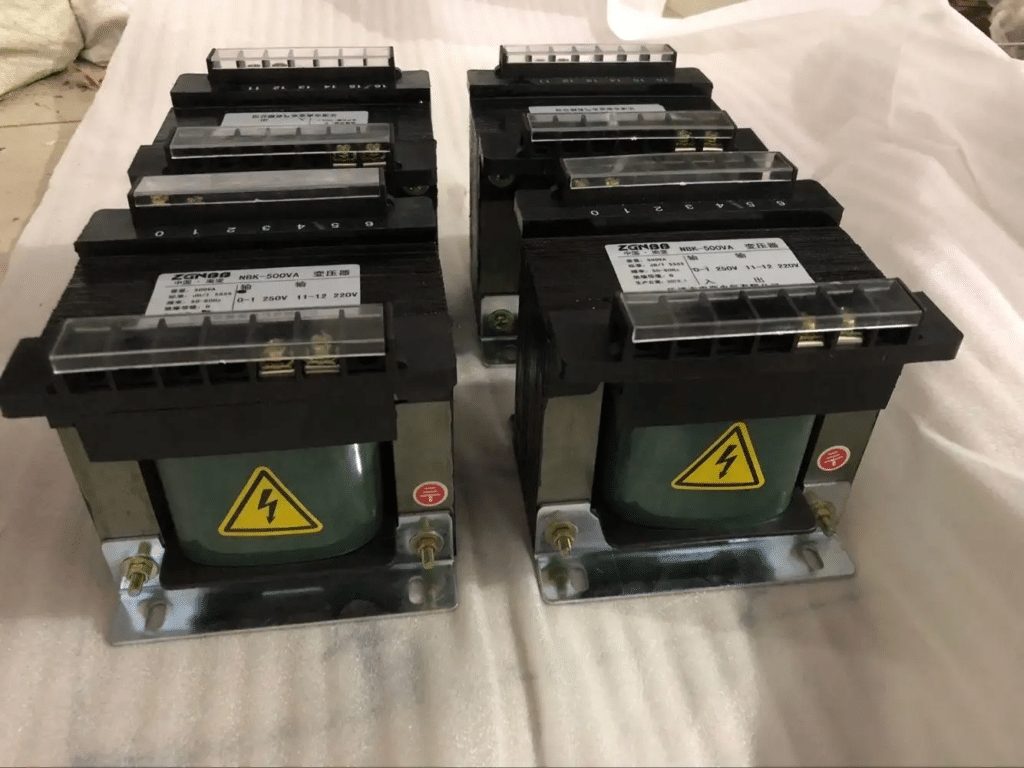

A control transformer is a small transformer designed to provide power to control circuits in electrical equipment.

It is used to isolate and reduce the voltage of the mains power supply, usually to provide a lower voltage for control devices such as relays, timers and solenoids.

Control transformers are commonly used in industrial applications where remote control of electrical equipment is required or where voltage levels in control circuits need to be reduced.

They are also commonly used in electronic and automation systems where stable and isolated low voltage power supplies are required for sensitive electronic components.

Control transformers can be single-phase or three-phase and come in a variety of sizes and ratings depending on the application. They typically have high winding resistance and low leakage inductance to provide a stable output voltage with minimal voltage drop under load. They may also include other features such as thermal overload protection, multiple output voltages, and grounding options.

Type of control transformer

Our common control transformers mainly include the following types:

- Single-phase control transformer: There is a primary winding and a secondary winding, which is used to step down the voltage level in the single-phase control circuit.

- Three-phase control transformer: There are three primary windings and three secondary windings, which are used to step down the voltage level in the three-phase control circuit.

- Buck-Boost Transformer: Controls the step-up or step-down level in a circuit designed to provide a specific voltage ratio based on the winding configuration.

- Multi-tap transformer: Multiple taps on the primary and/or secondary windings to select different voltage levels.

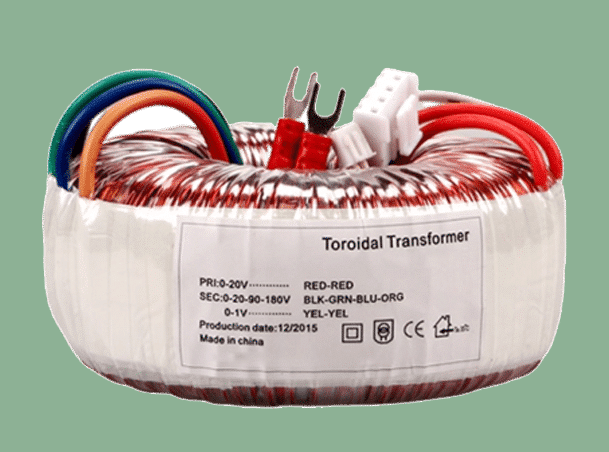

- Toroidal Transformer: The shape is cylindrical with a hole in the middle, used for occasions where space is limited.

- PCB Mount Transformers: Designed for direct mounting on a printed circuit board (PCB), typically used in small electronic devices.

Control transformer applications

Control transformers are widely used in the industrial field, specifically in the following fields:

- Industrial control system: Provide low-voltage power supply for control equipment such as relays, timers, and solenoids to regulate industrial processes such as temperature, pressure, and flow.

- Motor Control Circuits: Control devices used to start, stop, and regulate the speed of motors provide low-voltage power.

- Lighting Control Systems: Provides low-voltage power to control devices that turn lights on, off, and dim them.

- HVAC Systems: Used in heating, ventilation, and air conditioning (HVAC) systems to provide low-voltage power to control equipment used to regulate temperature, humidity, and airflow.

- Process Control Systems: Provides low-voltage power to control equipment that regulates chemical processes, such as those used in water treatment, food processing, and pharmaceuticals.

Current transformers

A current transformer is a type of transformer that is used to measure the current flowing in an electrical circuit. It works by stepping down the current in the circuit to a level that can be safely measured by an ammeter or other measuring device. Current transformers are typically used in high voltage power systems, where it is not safe or practical to directly measure the current in the circuit.

Current transformers have a primary winding that is connected in series with the circuit being measured, and a secondary winding that is connected to the measuring device. The ratio of the primary to secondary windings determines the amount by which the current is stepped down. For example, a current transformer with a 100:1 ratio would step down the current in the circuit by a factor of 100.

Current transformers are an important component of many electrical systems, as they allow for safe and accurate measurement of current in high voltage circuits. They are designed to be compact and efficient, and are often used in applications where high voltage power is being transmitted or distributed.

Types of current transformers

There are many types of current transformers, our common types are as follows:

- Wire Wound Current Transformer: This type of transformer has a primary winding and a secondary winding and is used to measure current in single-phase circuits.

- Bar current transformer: with bar primary and secondary windings for measuring current in high voltage power lines.

- Window current transformer: has a split core that can be opened to allow the primary winding to be wound around the conductor under test. It is typically used in retrofit applications where it is not possible to disconnect the circuit under test.

- Rogowski coil current transformer: It adopts a flexible coil that can be wound on the conductor under test. It is typically used in high current applications where conventional current transformers are too large or impractical.

- Busbar Current Transformer: Designed to be mounted directly on the busbar and used to measure current in power distribution systems.

- Protective Current Transformers: Used in electrical protection systems to detect overcurrent conditions and trip circuit breakers or other protective devices.

Current transformer application field

Current Transformers (CTs) are sensors used to measure electrical current in power systems. They work by converting the high currents found in power lines into lower, more manageable currents that can be measured with standard instruments. CTs are widely used in a variety of applications, including:

| Application | Description |

|---|---|

| Metering | Used to measure the amount of electricity consumed by a customer. |

| Protection | Used to protect power systems from overcurrent conditions that can damage equipment or cause outages. |

| Control | Used in conjunction with protective devices to control the operation of power systems. |

| Monitoring | Used to monitor the performance of power systems and detect potential problems. |

| Diagnostics | Used to diagnose issues with power systems and identify potential faults or problems. |

Audio transformers

Audio transformers are devices that are used in audio systems to match the impedance between different components and to isolate the audio signal from interference.

Impedance is the resistance of an electrical circuit to the flow of electrical current. When different audio components have different impedances, it can cause distortion and reduce the quality of the audio signal. Audio transformers are used to match the impedance of different components, ensuring that the audio signal is transmitted with high fidelity.

Audio transformers can also help to isolate the audio signal from external interference, such as electromagnetic interference (EMI) or radio frequency interference (RFI). This can help to reduce unwanted noise and distortion in the audio signal.

Audio transformers are commonly used in professional audio equipment, such as mixing consoles, amplifiers, and recording equipment. They are also used in consumer audio equipment, such as hi-fi systems and headphones, to improve the quality of the audio signal.

Types of audio transformers

There are several types of audio transformers used in audio equipment. Here are some of them:

Input transformers: These are used to match the impedance of a microphone or other audio source to the input impedance of a preamp or other amplifier.

- Output transformers: These are used to match the high impedance output of a tube amplifier to the low impedance input of a speaker.

- Interstage transformers: These are used to transfer the signal from one stage of amplification to another.

- Line level transformers: These are used to balance and isolate audio signals in long cable runs.

- Reverb transformers: These are used in spring reverb units to match the impedance of the reverb tank to the rest of the circuit.

- Matched pairs: These are two identical transformers that are used together in stereo equipment to ensure consistent sound quality between the left and right channels.

- Isolation transformers: These are used to provide electrical isolation between a source and a load, which can help reduce noise and hum in the signal.

Note that the specific types of transformers used in audio equipment can vary depending on the application and the manufacturer.

Audio transformer application field

Audio transformers are used in various applications in the audio industry. Some key application areas include:

- Microphone preamplifier: Commonly used in microphone preamplifiers to match the impedance of the microphone to the input of the preamplifier. This helps improve the quality and clarity of the signal.

- Amplifier: Typically used in tube amplifiers to match the high impedance of the output tube to the low impedance of the speaker.

- Equalizer: EQ can be used to help balance and isolate different frequency bands.

- Recording equipment: Commonly used in recording equipment to match the impedance of different devices and provide isolation between different components.

- Broadcast Equipment: Widely used in broadcast equipment to help improve the quality and clarity of the signal.

- Guitar Effects Pedals: Sometimes used in guitar effects pedals to provide isolation between different effects and to help prevent noise and hum in the signal.

- Hi-Fi equipment: Audio transformers are used in high-end audio equipment to help improve sound quality and reduce noise and distortion.

Overall, audio transformers are important components in many different types of audio equipment, helping to improve sound quality, reduce noise, and provide electrical isolation between different components.

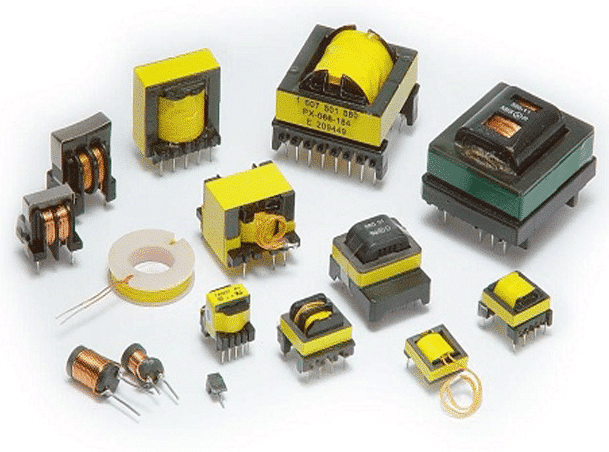

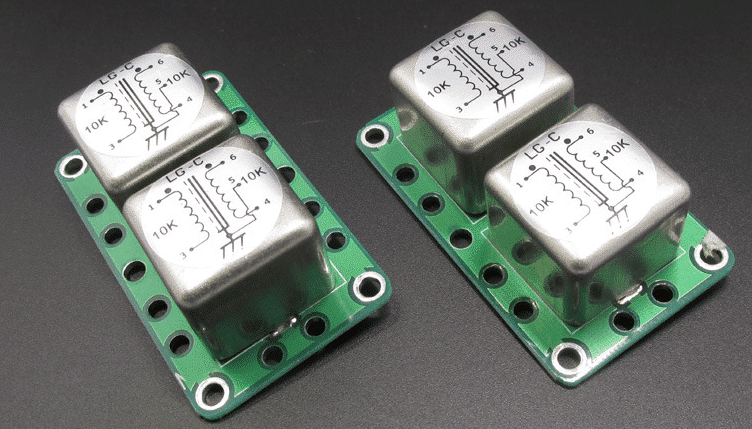

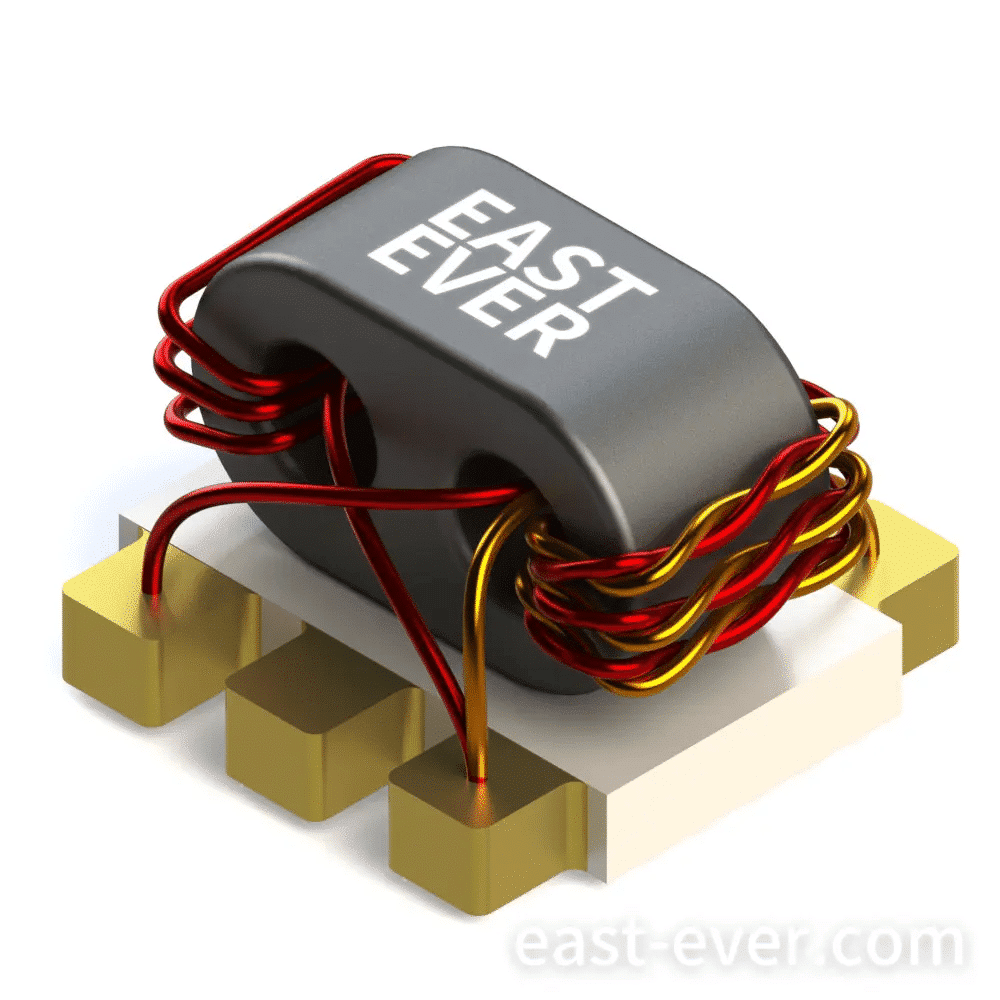

RF transformers

RF transformers are devices used in radio frequency (RF) circuits to transfer signals from one circuit to another. They are designed to work specifically with high-frequency signals, typically in the range of a few kilohertz to several gigahertz.

The basic principle of an RF transformer is similar to that of a regular transformer, in that it uses mutual inductance to transfer energy between two circuits. However, there are some key differences. For example, RF transformers are typically designed to work with much higher frequencies than regular transformers, and they often have a much smaller physical size.

One of the main uses of RF transformers is in impedance matching. Impedance is a measure of how much resistance a circuit has to a particular frequency. If two circuits have different impedance levels, it can be difficult to transfer signals between them without causing distortion or loss of signal strength. RF transformers can be used to match the impedance of two circuits, allowing signals to be transferred more efficiently.

RF transformers can also be used for other purposes, such as coupling signals between different stages of an RF circuit, isolating one circuit from another, or providing voltage or current transformations. They are commonly used in a variety of applications, including radio communications, wireless networks, and electronic instrumentation.

Types of RF transformers

There are several types of RF transformers, each with its own unique characteristics and applications. Here are a few examples:

- Air-core transformers: These are transformers that use air as the core material, rather than a ferromagnetic material like iron. Air-core transformers are often used in high-frequency applications where low losses and high Q-factor (quality factor) are important.

- Ferrite-core transformers: These are transformers that use a ferrite material as the core. Ferrite cores are useful in RF applications because they have a high magnetic permeability, which allows for efficient energy transfer at high frequencies.

- Balun transformers: A balun is a type of transformer that is used to convert between balanced and unbalanced signals. This is often necessary in RF systems where signals are transmitted over coaxial cables or other unbalanced transmission lines.

- Transmission-line transformers: These are transformers that are constructed using transmission lines, such as coaxial cables or microstrip lines. They are often used in RF filter circuits and impedance-matching networks.

- RF transformers with multiple windings: Some RF transformers have multiple windings, which can be used to create different signal paths or to provide multiple turns ratios. These transformers are often used in RF oscillators and other complex circuits.

- Toroidal transformers: These are transformers that have a toroidal (doughnut-shaped) core. Toroidal cores are useful in RF applications because they have low electromagnetic interference and can be made very compact.

RF transformers application field

RF transformers have a wide range of applications in radio frequency (RF) and microwave electronics. Here are some examples:

- Radio Communications: Typically used in radio transmitters and receivers to match the impedance of the antenna to the transmitter or receiver circuit. This helps maximize the energy transfer between the antenna and the circuit, improving the efficiency and performance of the system.

- Wireless Networks: RF transformers are used in wireless networks, such as Wi-Fi and cellular networks, to transmit signals between antennas and receiver or transmitter circuits. They are used to match the impedance of the antenna to the transmission line and provide voltage and current conversion as required.

- Electronic Instrumentation: Commonly used in many types of electronic instrumentation, such as spectrum analyzers, oscilloscopes, and signal generators. They are used to couple signals between different stages of an instrument and provide impedance matching and signal conditioning.

- Radar System: Used in radar systems to transmit signals between the antenna and the transmitter or receiver circuitry. They are used to match the impedance of the antenna to the transmission line and provide voltage and current conversion as required.

- Satellite communication: Used to transmit signals between satellites and ground stations. They are used to match the impedance of the antenna to the transmission line and provide voltage and current conversion as required.

These are just a few examples of the many applications for RF transformers. They are used in a wide range of industries including telecommunications, aerospace, defense and medical electronics.

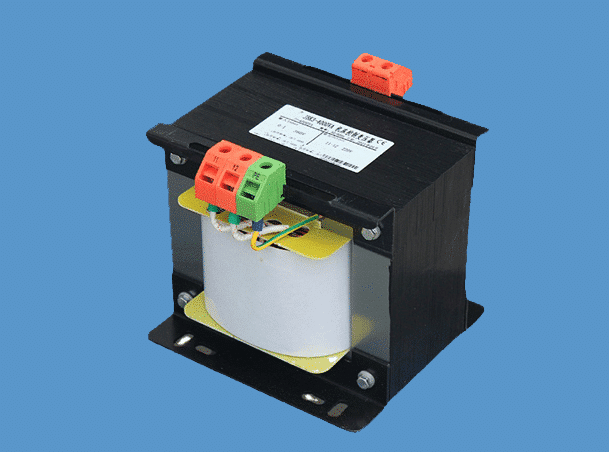

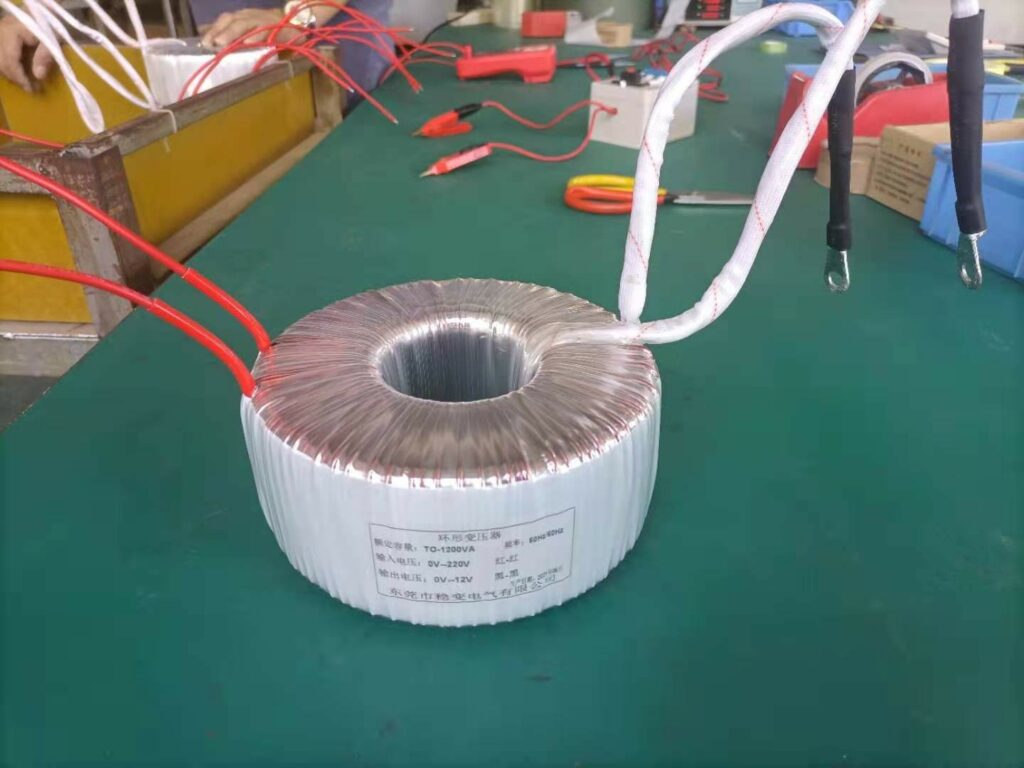

Toroidal transformers

A toroidal transformer is a type of electrical transformer that has a doughnut-shaped core. The core is made of a ferromagnetic material, such as iron, and is wound with wire to create the transformer’s windings.

The toroidal shape of the core has several advantages over other transformer shapes, such as rectangular or cylindrical. For example, the toroidal shape allows for a more efficient use of the core material, which can lead to better performance and higher efficiency. Additionally, the toroidal shape reduces the amount of electromagnetic interference generated by the transformer, which can be important in sensitive electronic applications.

Toroidal transformers are used in a wide range of electronic devices, including audio equipment, power supplies, and lighting systems. They are often preferred over other transformer types because of their compact size, high efficiency, and low electromagnetic interference. However, they can be more difficult to manufacture and may be more expensive than other transformer types.

Types of Toroidal transformers

Toroidal transformers are usually designed for audio, so there are not many other types, and they are all circular in structure.

Toroidal transformers application field

Toroidal transformers have a wide range of applications in various industries, including:

| Industry/Application | Examples |

|---|---|

| Audio Equipment | Power amplifiers, mixers, speakers, other audio equipment |

| Medical Equipment | MRI machines, X-ray equipment, medical imaging equipment |

| Lighting Systems | LED lighting systems, lighting controllers, dimmers |

| Industrial Equipment | Welding machines, motors, generators, voltage regulators |

| Telecommunications | Telecommunication equipment, antennas, power supplies |

| Aerospace/Defense | Avionics, radar systems, military communication equipment |

| Transportation | Automotive electronics, train controls, marine equipment |

| Power Generation | Power plants, renewable energy systems, battery charging systems |

| Research and Development | Laboratories, experimental equipment, test and measurement |

Conclusion

After reading the above content, do you have enough understanding of transformer types?

Transformers are an integral part of electrical and electronic circuits because they efficiently transfer electrical energy from one circuit to another.

There are many types of transformers available, here we have listed only 10 of the common ones each of which has unique characteristics and applications.

Understanding the different types of transformers and their specific applications is critical to designing and building more efficient and reliable electrical and electronic systems. By choosing the right transformer for your circuit, you can ensure optimum performance and energy efficiency.

Content source

The Transformers Committee of the Institute of Electrical and Electronics Engineers (IEEE): https://www.ieee.org/standards/industry-standards/transformers.html

The International Electrotechnical Commission (IEC): https://www.iec.ch/standards/transformers/

The American National Standards Institute (ANSI): https://www.ansi.org/standards_activities/standards_boards_committees/transformers

The National Electrical Manufacturers Association (NEMA): https://www.nema.org/Products/Pages/Transformers.aspx

Transformer Association: https://transformer-assn.org/

All About Circuits: https://www.allaboutcircuits.com/textbook/reference/chpt-9/introduction-to-transformers/

Electronics Tutorials: https://www.electronics-tutorials.ws/transformer/index.html